Ventilation of the unsaturated zone (venting)

Aerate the soil by an air circulation of air, like when ventilating a room just painted, except that here the vapors are conducted to a treatment unit.

Aerate the soil by an air circulation of air, like when ventilating a room just painted, except that here the vapors are conducted to a treatment unit.

Intervention on complex materials and strong reduction of dust at the workplace.

Sort the fractions of the soil by size (gravel, sand, silt, fines), in the case where the pollution binds to one, and recover the other fractions.

Finishing of the supports on industrial coating or buildings cladding.

Inject into the water table a reagent, which will destroy oxidizing or oxidized pollutants.

Put in place very precise pumps, which will pump only the layer of pollutant floating on the surface of the water table, to limit the volumes to be treated.

Pump dissolved pollutants into the aquifer and then extracting them by physical separation or chemical modification processes.

Create a depression by pumping, to prevent polluted water from spreading.

Use oxidation or reduction reagents to destroy soil pollutants in a cell dedicated for this purpose.

Inject a superoxide into the water table, which will destroy the pollutants, almost like we treat the water of a swimming pool.

Produce biogas continuously and regulated from semi-pasty or solid products, especially from the food industry or agriculture.

The patented METHACORE® principle is based on the Upflow Anaerobic Sludge Blanket (UASB) technology, which uses a bed of granular sludge in a rising flow.

Vigorously stir the soil in water, and then separate them, to pull different pollutants out of the solid matrix.

Activate the microbiological functioning of the soil with agricultural techniques and machines; very simple but takes up space.

Use aerobic granules and remove 95% of the nitrogen compounds and 94% of the phosphates without reagents. All effluents including significant organic pollution can be treated by this process.

Aspirate mobile phases (up to 3: vapors, dissolved pollutant and pure pollutant), to treat them on the surface, in specialized equipment.

Extract the polluted soil into the rules of art to direct it to a treatment technique, on or off site. In doing so, the affected area has already been cleared.

Enclose the pollutant in a sealing complex to prevent any pollutant migration, on site, or in a storage center.

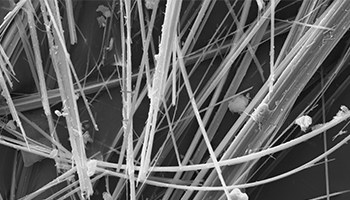

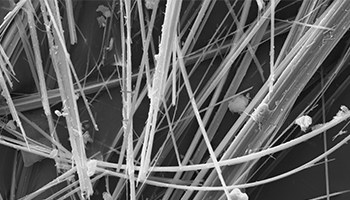

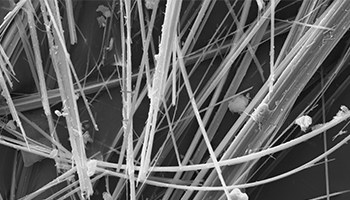

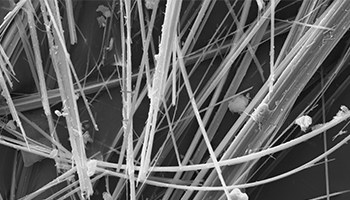

Sustainable recovery of asbestos materials in the active zone.

Condition the soil, to heat it and vaporize the pollutant which is then trapped in special devices (condensers, filters ...) (see venting for its capture).

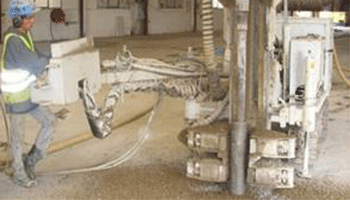

Piloting the most advanced technologies by our operators

Intervention of mechanical devices to ensure the removal of the heaviest MCA.

Condition the soil to create a solid biological reactor, in which the biodegradation conditions are optimized (air, nutrients, moisture ...).

Place heating elements in the ground, to vaporize the pollutant, which is then trapped in special devices (condensers, filters, ...) (cf venting for its capture)

Set up a multilayer complex, to isolate the polluted soil, preventing the spread of the pollutant and its contact with the outside.

Aerate the soil by air circulation, to allow microbes to destroy pollutants.

Inject air into the water of the aquifer, to dissolve the oxygen, which allows the microbes to destroy pollutants.

Put in place a reagent that will treat pollutants dissolved in the aquifer, as it flows.

Inject air into the water of the aquifer to extract the dissolved pollutants; is coupled with a venting to avoid pushing the pollutant to the atmosphere.

Thanks to its technical expertise in asbestos and lead removal and soil remediation, but also in the recovery of waste and industrial effluents, VALGO masters a whole range of innovative treatments to meet your remediation and decontamination needs.

Regarding asbestos removal, VALGO has proven expertise in traditional techniques to remove asbestos from buildings and also offers innovative techniques for treating asbestos soils, for example.

For your soil and groundwater remediation operations, you can count on the rich experience of more than 3,000 remediation projects operated by VALGO, whose engineers always favor in situ techniques in order to limit the carbon footprint of these operations. When in-situ treatment is not possible, VALGO chooses the best soil contamination treatment methods like cleaning the polluted soil on site or excavating it directly for treatment or storage outside the construction site, always choosing its partners carefully.

This technical expertise gives VALGO a particularly detailed knowledge and experience enabling it to provide you with optimal solutions for depollution, asbestos and lead removal, combining performance, cost control and environmental protection.